Container Grades

|

New One Trip

A one trip container is a water tight container that has only been used on one overseas

cargo load. One-trip containers have the best-looking exterior.

IICL Standard

This is leasing company standard (CAI, Triton, Trader). Unit is structurally sound, there are

no leaks. And unit has very little to no surface rust there are no rust holes anywhere. Must have current CSC plate. No holes, cuts, tears, or cracks in panels, doors or roofs.

|

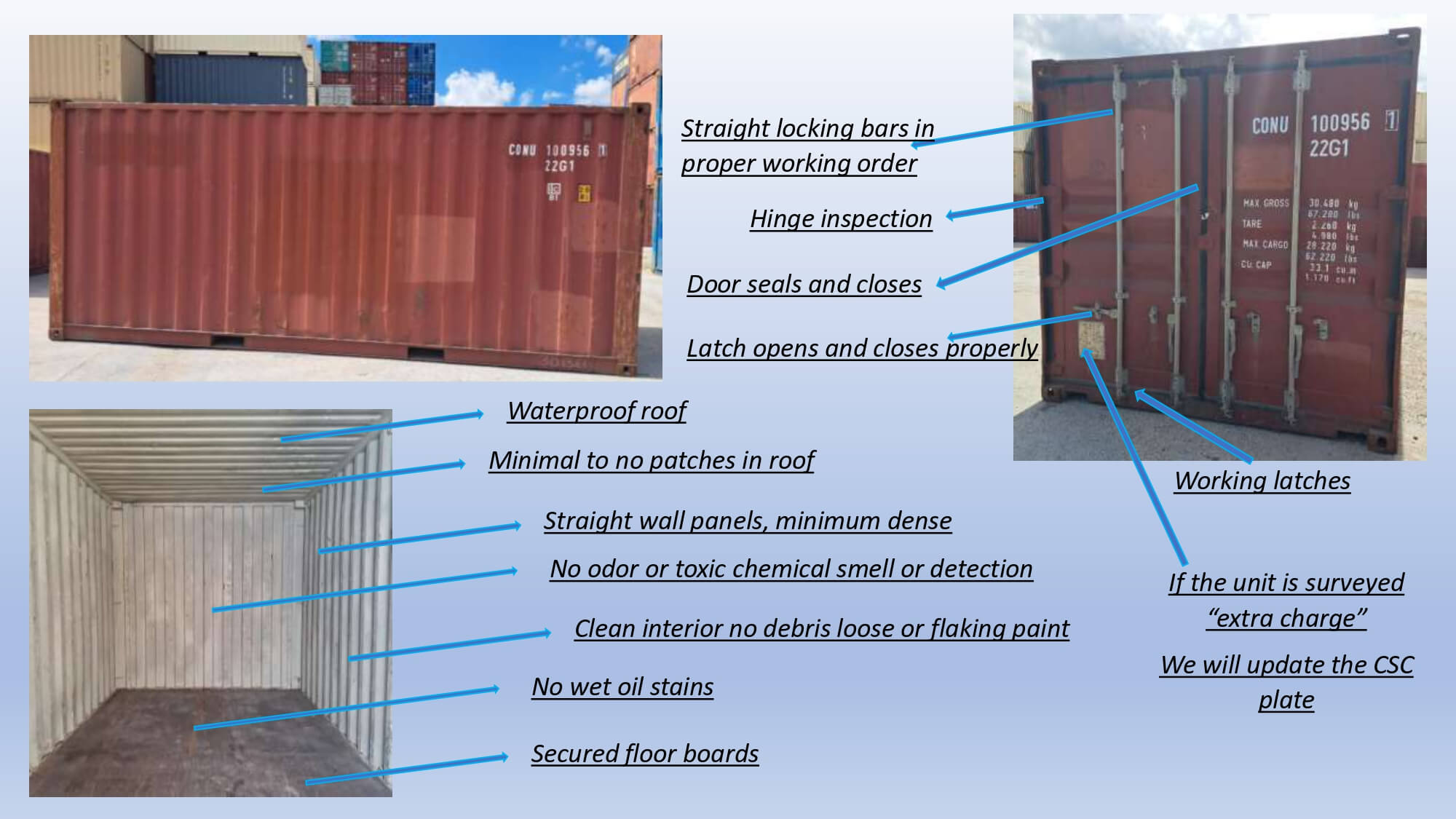

Cargo worthy

Unit may have some dents in panels as long as the interior cube is not affected. Unit is

structurally sound, there are no leaks. There are no rust holes. Unit can have 50% or more surface rust. Must have CSC plate.

Wind water tight

There are no leaks. Unit is not structurally sound but one is guessing that it may be okay

to safely move by truck. As long as there are no outright holes in the floor it can have broken flooring. Can be covered in surface rust but no rust holes.

As – Is

Is essentially a container in need of some sort of repair(s). The container may have a wide range of items to be addressed such as broken flooring, holes in the roof or sides, undercarriage issues, structural problems and other moderate to high cost of repair(s).

|

|

|

|

|

IICL5 Standards for Containers

- Containers are to be in safe and sound condition.

- Containers are to be water and light tight.

- Containers are to be free of any defects which could affect container safety or the ability to carry cargo.

- Containers are to be free of debris and dunnage.

- Containers must have at least 4 legible unit numbers, plus 4-digit ISO Code on door, a weight panel and CSC plates with current re-inspection sticker.

- All steel repairs are to be made with welds. Caulking, bondo, and tar tape are not acceptable as substitutes for welding.

- Any corrosion when hit with a chipping hammer resulting in a hole being punctured is unacceptable.

- No cracked welds on the webs of prime structural components, i.e., rails, posts, crossmembers, cams and keepers.

- No holes, cuts, tears, or cracks in panels, doors or roofs.

- Vents are to be functional and watertight or closed off.

- Doors are to be operable, water and light tight and sealable.

- No dents interfering with interior cubic capacity or exterior ISO dimensions in roof, sides or front panels. No dents exceeding 1” in door panels.

- Dents not to exceed 1” in tunnel recess.

- Dents in corner posts to be no more than ¾”, top rails 1”, front and rear headers 1”, all other rails 1 ½”.

- Floors not to be bowed up more than 1”.

- Floor separation not to be more than 3/8” at fastener.

- Roof bows not to be more than 1” into interior.

- No cracked, missing or corroded crossmembers in a row.

- No tears in bottom rail flanges – dents, bends OK

- No cracked, broken, missing or corroded door hinge on either door.

- For opentops, no missing roof bows.

- For opentops, door headers must be operable and no pins missing.

- For opentops, tarp cables must be complete – no splices.

- For opentops, if tarp has small hole(s) - patch

- For opentops, if tarp has large hole(s), too many small holes, are worn or tattered – replace.

|

|

|

|

|

|